Overview

3D fashion development is becoming a key foundation for AI, which has moved from hype to real use. Reports from The Business of Fashion and McKinsey show that many fashion leaders now believe AI is a big driver of value by 2026. It’s changing how creativity, speed, and decisions are made in design, merchandising, and operations.

But there’s still a gap in how AI is being used. Even though more companies are trying to adopt AI, not many have fully integrated it into the process of making clothes from design to production in a way that supports making clothes, scaling them up, and ensuring quality.

Experts say AI, including tools like generative models, predictive analysis, and digital twins, could bring hundreds of billions of dollars in value. But this value only happens if the creative ideas are based on real technical data, not just looks that are imagined.

This is where many current methods fail.

Why AI Visuals Are Insufficient for Production

AI is great at making eye-catching images. But factories need accuracy, not just guesses. Production can’t start without:

- Confirmed fabric details (e.g. drapes, stretches, thickness, density,…)

- Correct pattern blocks and grading rules that ensure fit and size are the same.

- Construction details (e.g. seam sizes, stitch types, inner linings, reinforcements,…)

- Manufacturing tolerances, which can mean the difference between an approved sample and a costly rework.

When these things are missing or not right, the first samples don’t work, time gets longer, and more materials are wasted, making things less efficient, more expensive, and less sustainable. Industry experience shows that AI design outputs often miss important construction details, fabric digitisation is hard, and AI can imagine fabric behaviour that looks real but breaks the rules of physics. Without real validation, the difference between what’s designed and what can be made increases.

Where AI Adds Value, With Guardrails

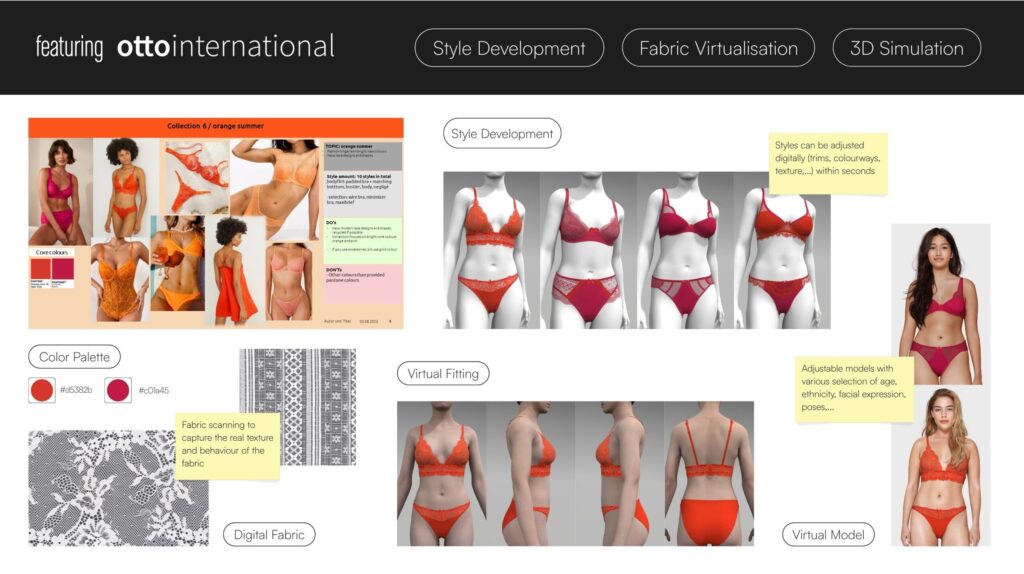

A better way is growing the industry. AI works best when it helps with creativity and making things faster, not when it replaces technical steps. Some of the most useful applications include:

- Rapidly creating ideas for shapes, patterns, and details.

- Using AI to filter and compare fabrics based on real measurements.

- Automating repetitive jobs (e.g. making bills of materials and organising tech packs).

- Creating marketing and online visuals once technical accuracy is confirmed.

Brands that use digital twins and AI-assisted tools see faster timelines, but only after building a strong base of measured, real garment data.

A Scalable AI-Led Workflow

Looking ahead to 2026, leading fashion companies are finding that AI is most useful when it’s part of the whole process, not a separate solution. Instead of seeing AI as a whole answer, top teams use it to make decisions, but base their results on proven technical systems. This keeps creativity moving fast while keeping production reliable. A confident process usually follows this path:

- Using AI for early ideas and concepts.

- Validating 3D designs with actual fabric data and physical behaviour.

- Creating production assets with the help of technical experts.

- Using AI and 3D tools to make visuals once products are ready for production.

Companies that mix AI with strong 3D and technical skills get to market faster, need fewer samples, and are more accurate without increasing the risk of production problems.

featuring’s Credible Role

As AI helps with the creative part of fashion, the industry is looking for partners that can connect the spark of inspiration with the actual ability to make clothes. featuring helps by:

- Digitising fabrics with real, tested physical properties.

- Creating 3D samples that are accurate, reducing risk before making physical prototypes.

- Making patterns that are ready for production with correct grading and how the pieces are put together.

- Using AI to create visuals only after the garments are technically sound.

This ensures that inspiration leads to products that are easy to make, can be made a lot of times, and are high quality, not just nice to look at.

Key Takeaways

- AI offers amazing speed in creativity, but it can’t create actual production instructions on its own.

- Real technical data (like how fabric behaves, how it’s built, and acceptable tolerances) is still crucial.

- Combining AI, 3D, and human skills is now the most reliable way for the industry.

- Brands that understand both the power and the limits of AI will lead the next big changes in fashion.